JPB Système, one of the leading manufacturers of cost- and time-saving technology solutions for aerospace, aeronautic and other industries, is makinrg 30 years of business as it opens a new 4,000 m² manufacturing facility in Poland, Eastern Europe. The new facility will significantly increase JPB Système’s manufacturing capacity by +60% and reinforces the company’s commitment to meeting growing aircraft industry demand from the region, while paving the way for future diversification and innovation.

The company is also launching a new digital transformation program, leveraging precise data to enhance production planning, improve material efficiency, and reduce energy consumption. This is expected to empower its customers with smarter, more efficient, and environmentally responsible solutions that contribute to long-term operational and financial benefits.

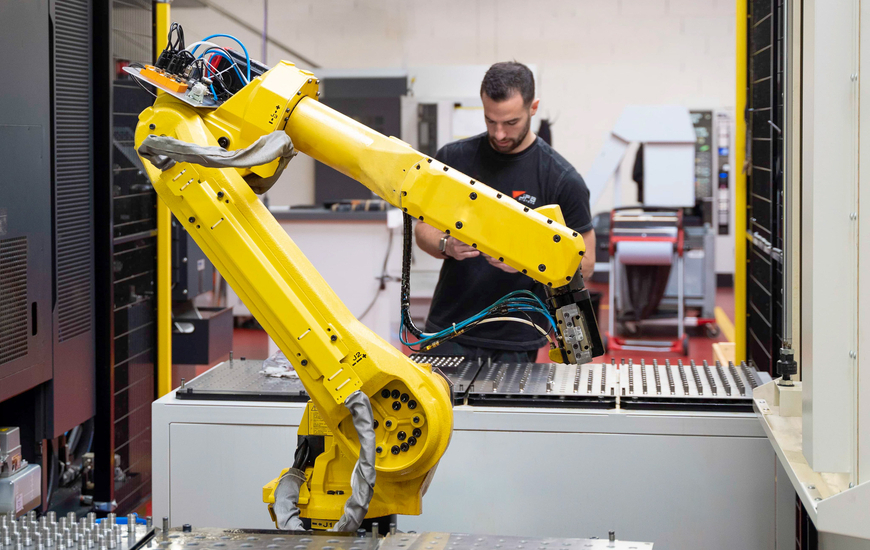

Driven by strong market growth, particularly in the aircraft industry, the expansion of JPB Système’s Eastern European operations is a strategic move to meet the increasing demand for its precision-engineered solutions. Located near Rzeszow Airport, close to major aircraft suppliers and JPB Système partners like Pratt & Whitney and MTU Aero Engines, the new facility is equipped with advanced milling machines to enhance production efficiency, along with state-of-the-art inspection and marking technology to ensure stringent quality control. Furthermore, JPB Système’s new Poland-based facility will have the capacity to handle and deliver products much faster, directly to key customers in the region.

Additionally, it will enable the company to serve new application areas requiring high reliability fastening solutions such as defence, rail, amusement parks, and ski lifts.

Damien MARC, CEO of JPB Système, comments: “As the world’s leading supplier of self-locking devices, we have a range of solutions for some of the most exacting and regulated industries in the world. And in 2025, the aircraft industry faces several key challenges, including supply chain disruptions, sustainability and decarbonisation, as well as spiralling costs and geopolitical uncertainty.

“In recognition of these and to better support our customers in Eastern Europe, we will now also manufacture all our products – including the leading Lulylok™ B-nut solution – locally. This will enable us to streamline production, customer service, and through our new digital transformation program – in time – further unlock additional and exceptional levels of sustainability and CO2 reduction,” he adds.

-

-

25 March 2025