by Gianluca Cicala*

University of Catania and Polytechnic of Milan joined their forces to develop novel materials for Additive Manufacturing. The main focus in this research was on fused deposition modelling (FDM) techniques and it was presented in a paper on Journal of Applied Biomaterials and Functional Materials.

The need for engineering plastics tailored for additive manufacturing is now compulsory and it was the driving force for this research. In order to overcome the limitation of temperature resistance (i.e. HDT) the research group developed, jointly with the company Roboze, some novel Polyetheretherketone (PEEK) filaments and some carbon fiber reinforced filaments.

PEEK is a valid alternative to implantable metal (e.g., stainless steel) because of its excellent biocompatibility combined with good strength and stiffness. There are PEEK grades, like Cytec APC-2, which are qualified for aerospace use too. PEEK is also widely used in many other applications because of its high chemical resistance.

PEEK filaments were produced on a pilot plant available at the University of Catania. The filaments showed very good fiber diameter tolerance (± 0.03 mm). PEEK filaments can be printed using the Roboze 400+ machine (Fig.1) which has been developed by the Roboze team specifically to work at the high temperatures (ie. ~400°C) need to print PEEK.

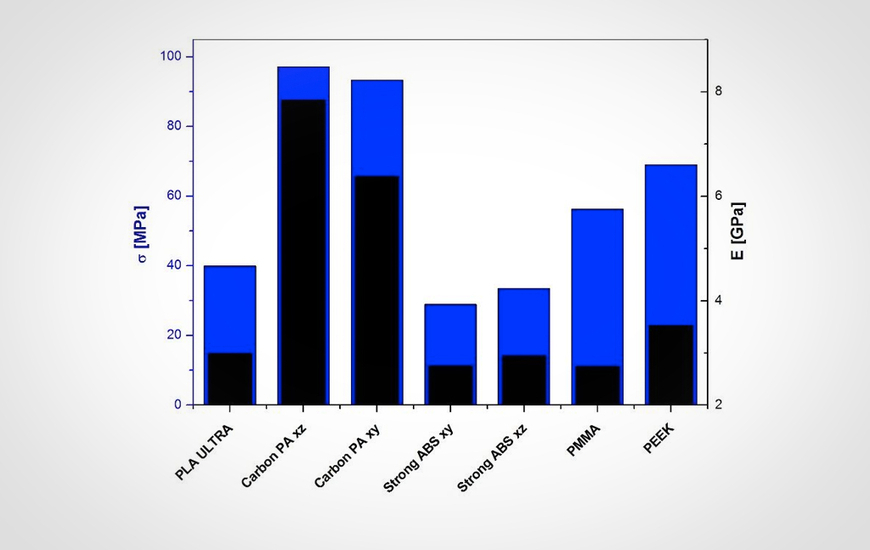

Peek filaments were thoroughly characterized in terms of their mechanical properties (Fig. 2) showing very good mechanical properties in comparison to other commercial filaments. Moreover, thermal resistance test were carried out.

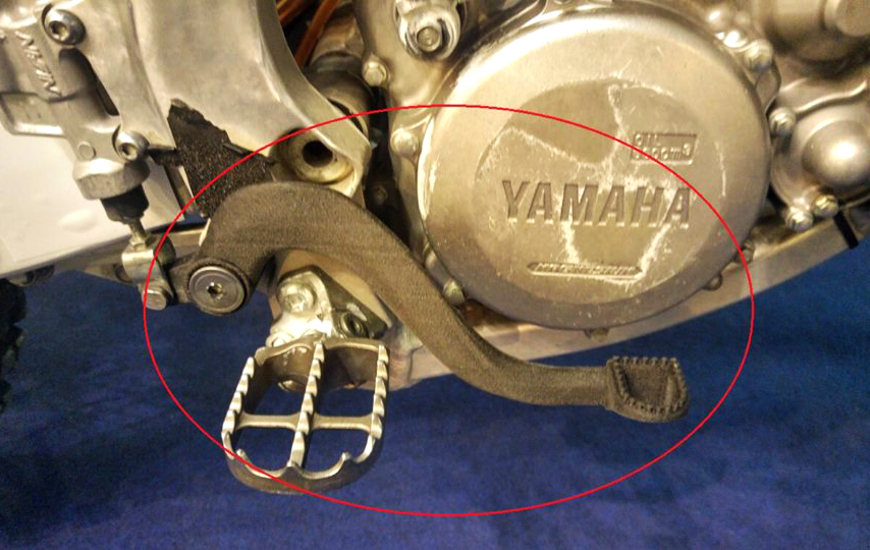

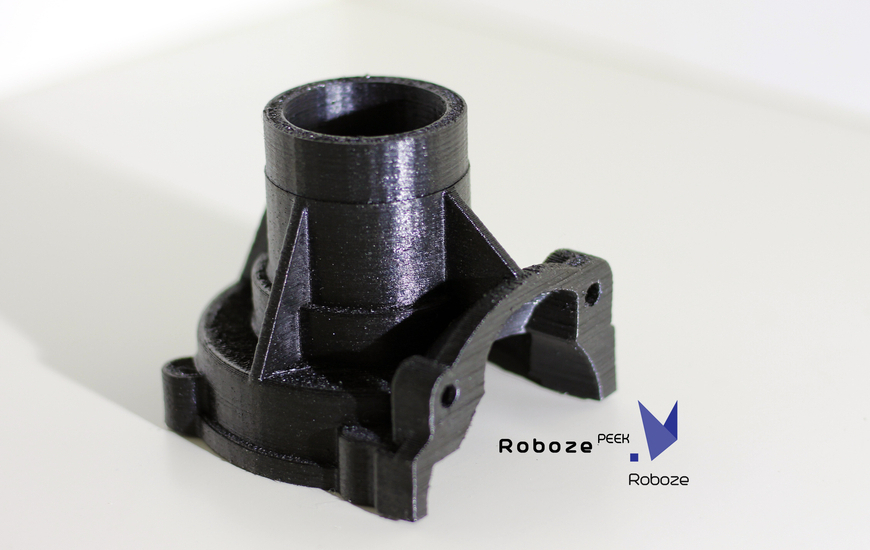

Based on this results Roboze developed with their customers different functional parts. Fig.4 shows a PEEK component which is now operating on a production plant. A water pump (Fig.5) for automotive application has been fully printed in PEEK and it is now under operative testing. When higher tensile and flexural properties are needed carbon reinforced nylon has been used (Fig.6).

The successful development of PEEK filaments opens up many new possibilities to increase the use of FDM in functional applications. Roboze and the teams at University of Catania and Polytechnic of Milan are at the forefront of these development and are ready to launch new engineered filaments.

* Engineer and Professor (PhD)

University of Catania

-

-

23 February 2017