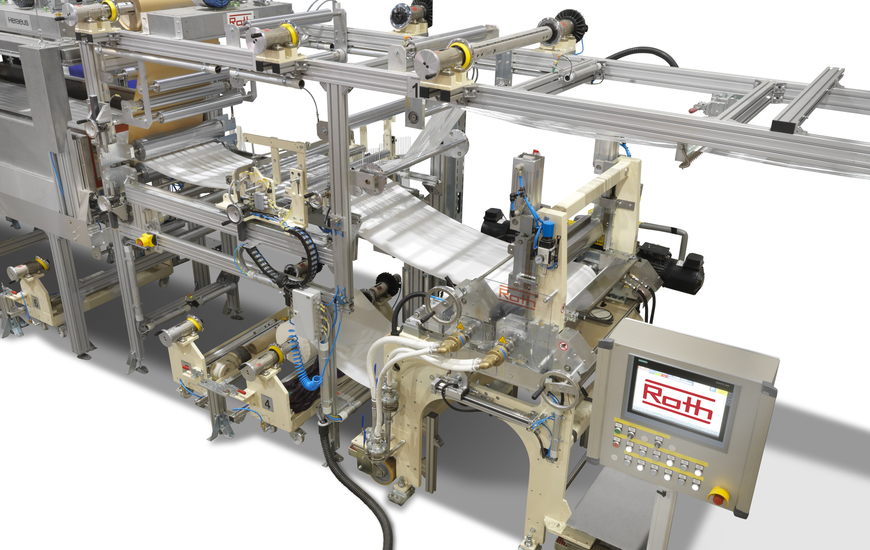

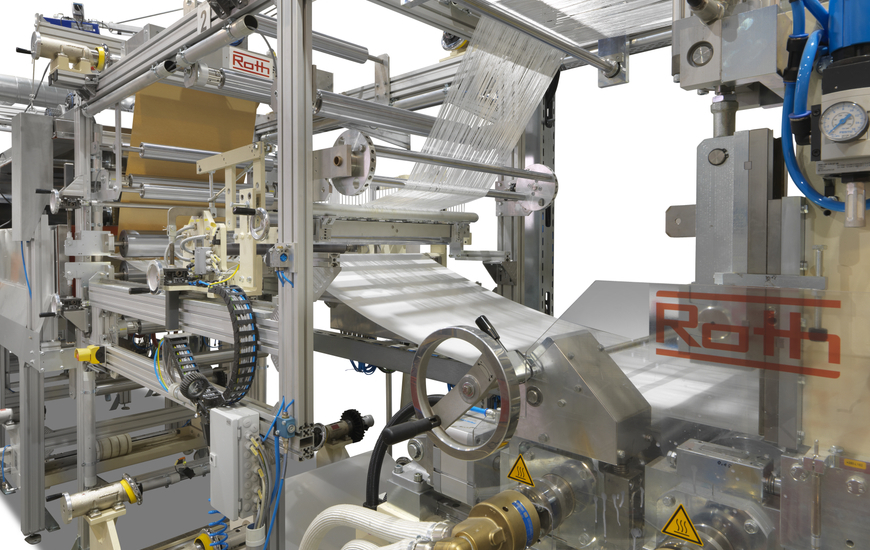

Roth Composite Machinery located in Steffenberg offers a laboratory for carrying out preliminary tests and process development as regards the manufacture of prepreg and organic sheets. Since the commissioning in 2017 customers have made use of the laboratory plant for production tests successfully. During current trials, Roth Composite Machinery has produced Lightweight Prepregs (particularly light semi-finished fibre composite materials) having a fibre surface weight of 75 g/m².

For the current test at a process speed of 15 m/min, Roth Composite Machinery used 12 K carbon fibres having a fineness of 800 tex. As matrix material, “hot-melt epoxy“ has been used and prepregs with a resin surface weight of 25 g/m² and a width of 255 mm have been produced. The Laboratory Line currently offers a fibre spreading unit with a working width of up to 600 mm.

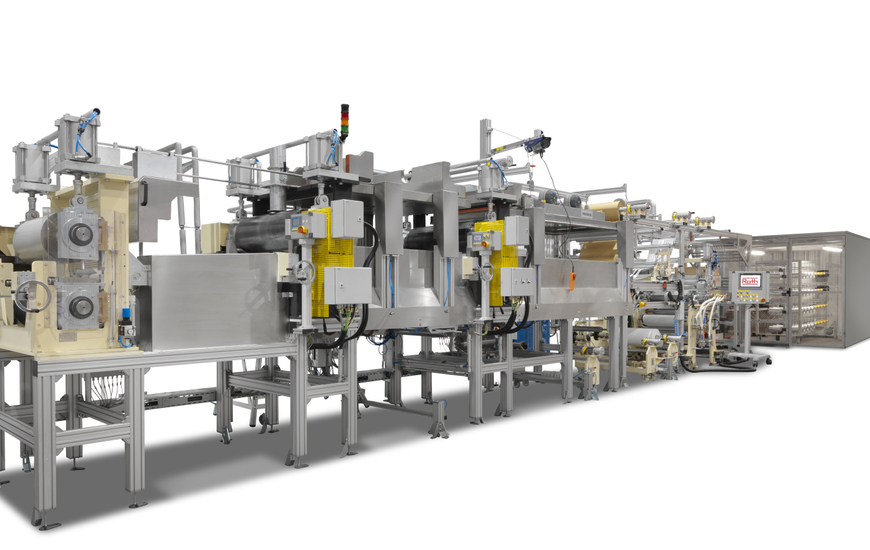

Prepregs of this kind are used in most diverse industries. The company from Steffenberg develops machines for the manufacture of prepregs according to individual customer requirements. They are suitable for applications in the sports and leisure industries, the aerospace sector, the automotive industry, the ship and boat building area, in the building and bridge construction or in airplane structures. The know-how of Roth Composite Machinery is based on its experience of more than 50 years in the manufacture of Prepreg Plants. The manufacturer invested roughly one million Euro in this laboratory line.

-

-

22 January 2019