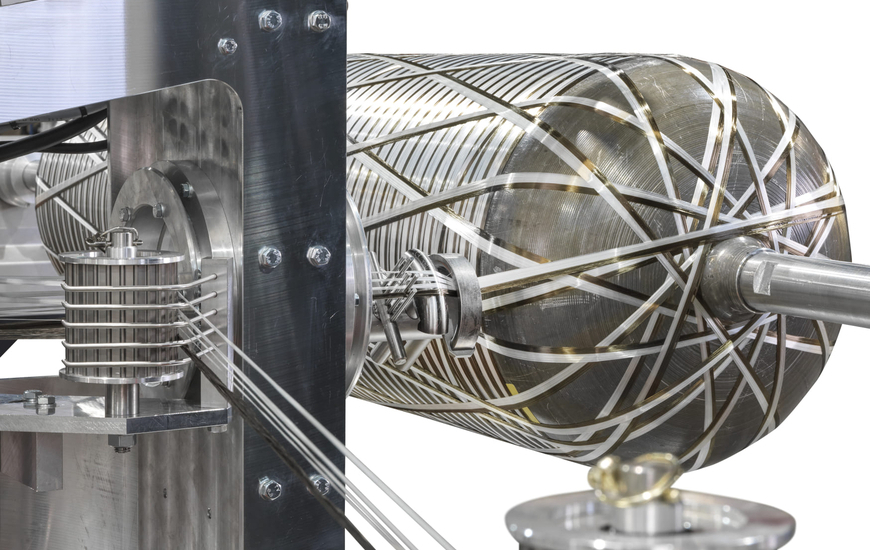

With an innovative machine concept, Roth Composite Machinery is setting new standards in mechanical engineering for the manufacture of products by using the filament winding process (fibre winding technology).

The company from Steffenberg now offers the Filament Winding Machine FWA 1 Duplex. The new process technology enables the winding process from both sides of a spindle and thus halves the production times compared to standard machines.

“After successfully launching a system speeding up filament winding processes by a multiple with the development of the Rothawin technology, we are presenting another innovation. Our new FWA 1 Duplex Machine for the large-scale production of pressure vessels, particularly for the automotive industry, achieves double productivity compared with our current world-leading standard“, states Dr. Andreas Reimann, General Manager at Roth Composite Machinery.

“While the production lines based on the Rothawin technology aim at the manufacture of small compact vessels primarily used for cars, the new gantry machine generation is addressed to the highly productive manufacture of vessels for commercial vehicles and trucks. Compared to our conventional multi-spindle machines, the production process is 10 to 15 percent faster. A particularly strong frame construction with an additional spindle drive on the opposite side keeps this dynamic and, in addition, the doubled fibre volume under control with ease“, Dr. Andreas Reimann continues.

-

-

26 November 2021